When one of McClure Engineering Company’s (MEC) skid-mounted control buildings arrives on site, it is a complete package, programmed, wired and specifically designed for the site conditions where it will support efficient operations from the day it arrives.

As a team of former operators, the instrumentation and controls team understands the nature of the oil and gas industry, so from the wiring and layout to the fabrication and shipping, a detailed focus on efficient design and continuous improvement ensures their control buildings are high-quality, durable and ready to adapt to the changing needs of the owner or operator.

As a team of former operators, the instrumentation and controls team understands the nature of the oil and gas industry, so from the wiring and layout to the fabrication and shipping, a detailed focus on efficient design and continuous improvement ensures their control buildings are high-quality, durable and ready to adapt to the changing needs of the owner or operator.

“As someone who has worked in the field, I understand how important efficiency, usability and durability are,” said Randy Sambursky, team leader of EPC projects with Enterprise Solutions. “We are always looking for ways to make the buildings better, so we focus on continuous improvement from the initial design phase through fabrication and delivery.”

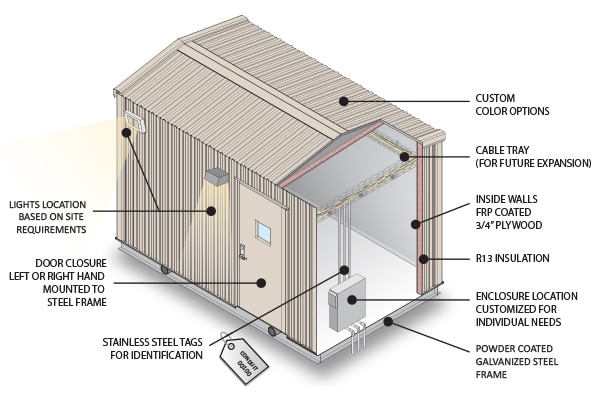

One of the features designed with the expansion of operations in mind is the optional cable tray and railing around the top of the building interior. This allows for equipment and panels requiring additional wiring to be added at a later date without running extensive conduit to the breaker panel or from panel to panel, which can be time consuming and costly.

The building’s air conditioner is placed in a sleeve, so if it were to be serviced or replaced, it can be easily removed without the need for additional tools. Additionally, the interior of the building is constructed with high-grade fiberglass reinforced plastic (FRP) covered three-quarter-inch plywood, which provides stability and flexibility for operators.

“Not only is the FRP both chemical and bug resistant, but it is also extremely sturdy and allows the operators to conveniently hang equipment anywhere on the inside of the building,” said Sambursky. “For the frame, we use powder coated galvanized steel to give the building’s exterior industrial-grade durability in the field.”

For the team, designing an efficient control building also involves considering the environment surrounding the building, and customizing the building’s design based on the site and customer’s needs.

“During the design, we look at the station footprint, and the building’s future surroundings,” said Sambursky. “Then, we position the programmable logic controller (PLC) and equipment inside the building to accommodate the shortest field conduit runs, so there is never a need to trench around the building. We also plan the position and layout of the exterior lights based on the site layout. This can save operators the task of installing additional light poles on the site.”

Skid-mounted control buildings are designed for durability and efficiency.

The direction of the door swing is determined on a site-by-site basis, so the door opens against the prevailing winds. This way, if winds catch the door, it will close rather than slam against the building or be torn off its hinges. Additionally, the door closures are mounted to the steel frame to improve stability and durability.

“One of the more challenging sites we worked with was in a flood plain, but we were able to deliver the building in less than six weeks, and design a site plan, so even if the area floods, the building will remain dry,” said Sambursky.

To protect the building from flooding, it was installed on concrete piers that were poured on top of helical piers. The piers were driven into the ground deep enough to provide stability, and a set of stairs leads up to the elevated building entrance.

“Some of these buildings require quick turnarounds, and it used to be a challenge to guarantee delivery dates, but we knew this was a critical piece to maximizing uptime for operators. So, our operations and shipping partners are now located directly across the street from one another,” said Sambursky. “It’s just one more way we’ve been able to maximize efficiency — something we are able to pass along to our clients.”